Here's a short video of some engraving we did in the clasp of a pearl bracelet. The customer wanted her first initial engraved on the clasp. The clasp is set in shellac to hold it in place while we engrave it.

There are several methods we use when making a ring. We've discussed handmade rings as well using computer-aided design (CAD) in previous blog posts. Another method we sometimes use is casting a ring from a mold. This method is useful when replicating an existing piece of jewelry.

Sometimes we want to make more “copies” of an existing design, or sometimes we need to make additional components for a piece of jewelry (a ring head, or a bezel, or whatever interchangeable part is needed). Regardless of the project, the first step is to make a mold of the item in question. We take the existing ring or component, and we place it in container with eight sheets of rubber surrounding it. The container is placed in a hot press where it remains for about 40 minutes, during which time the rubber melts around the ring or component, and makes a perfect mold of it. Along with the ring, a metal stem is placed in the container in order to create an opening where the wax will be injected at a later time.

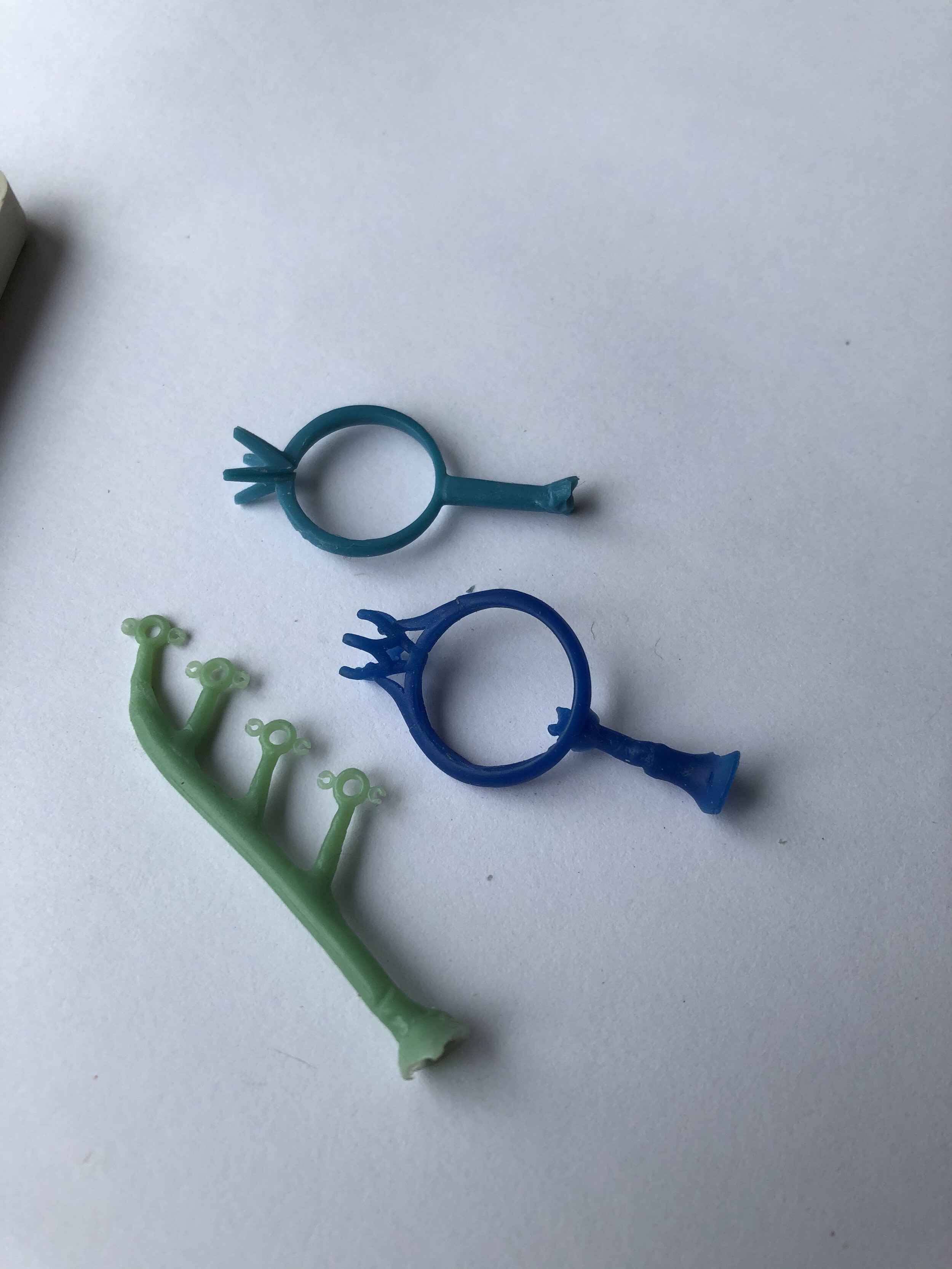

Examples of various wax molds: a set of small bezel settings for a necklace, and two different styles of engagement rings.

Once the rubber mold has been removed from the vulcanizer, cooled and hardened back to its original state, a blade is used (with a very special and precise technique) to cut the mold open in such a way that it can be closed back tightly in order to make the wax duplicate.

A rubber mold, which has been carefully cut so that it can be closed tightly anytime it is reused.

Wax flakes, as pictured below, are placed in a wax injector and melted so that they can be injected into the mold. Using air pressure, the wax is shot into the mold through the opening.

Wax flakes used for making models of jewelry.

The wax injector heats up and melts the flakes.

The melted wax is shot from the injector into the mold.

We make several wax replicas so that we can be sure to have one that comes out perfectly. Sometimes it takes several attempts in order to get the perfect wax model.

Several models are made so that the best one can be chosen for casting.

Once the waxes are done, we send them off to a casting company who does the final step of making them into a real ring-- either platinum or gold. They then send us the rings back, and we put on the final touches- polishing, sizing, setting, and then the ring is good to go!

Finished casted ring (after polishing & stone setting).

Any well-rounded diamond research process will include reading up on the 4C’s: cut, color, clarity, and carat— the four important characteristics to consider when choosing a loose diamond or a piece of diamond jewelry.

Carat size is probably the first thing you notice, but the cut & color are what determines whether or not the diamond will have that fiery sparkle and brightness to it. These interactive sliding graphics from the Gemological Institute of America will help you get a better understanding of the different diamond characteristics and why they are important.

In today’s world, you can customize almost anything: your vitamins, your shampoo, your suits and shoes… so why not customize your jewelry as well? Custom jewelry is nothing new, but thanks to modern technology it has become a more affordable (and thus, more popular) option.

Whether you have your own design in mind or just want to modify one of our existing designs, the process begins with a computerized rendering. The rendering gives a general sense of what the finished piece of jewelry will look like, and allows us to zero in on details like millimeter widths, number of diamonds, and other characteristics of the chosen design.

For example, we created a pavé halo engagement ring for a client last year. The design he had in mind was similar to one of our classic halo rings, but due to the size of the center stone (a 3.78 carat round brilliant) the proportions needed to be tweaked a bit.

The 3.78 carat diamond we set in a pavé halo engagement ring. The ring was customized to accommodate this larger center size.

Once the client was ready to move forward, we began making notes of what needed to be tweaked as well as any particular characteristics he wanted the ring to have. (In this case, one of the characteristics was a delicate pavé split at the top of the shank). A rendering was made based on the finger size, the size of the center diamond, and all our notes. We calculated proportions that would be dainty and accentuate the center diamond while also maintaining structural integrity.

A computerized rendering of the ring, which gives a rough sense of the concept. The main objective is to finalize and tweak the details before production.

Once the rendering is complete, it’s helpful to set up another meeting to go over the details in person and make sure everything looks right. This can be done via email as well.

After the rendering has been approved, the ring goes into production. This part of the process usually takes 3 to 4 weeks. The ring is manufactured by hand according to the specifications laid out in the rendering.

The finished product: a pavé halo engagement ring with a small outward taper & split at the top of the shank.

Making a custom piece of jewelry is a pretty easy process nowadays and it’s something we do frequently at our store. If you’re in the market for an engagement ring or a piece of jewelry and really want to make it your own, send us a message or make an appointment to stop by and discuss bespoke jewelry options!